Utility Cuts, Pavement Performance, and the Keyhole Solution

Improperly restored utility cuts can affect pavement performance and contribute to deterioration and reduced pavement life. Keyhole technology procedures and reinstatement processes are designed to minimize the impact of utility cuts on roadways and other paved surfaces by reinstating the paved surface to the operating condition that preceded the repair.

Pavement design

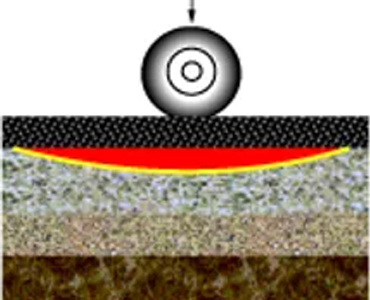

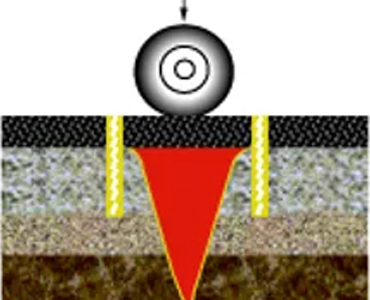

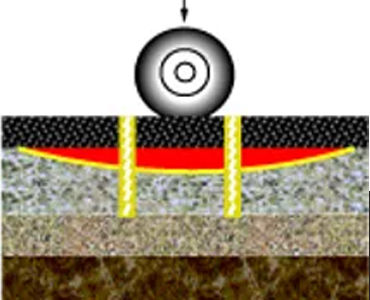

Pavements are designed as systems to share the vertical wheel load laterally across the paved surface, thereby reducing the vertical pressure on the sub-grade. The diagram below illustrates how pavements are designed to carry load and the difference in performance characteristics between roads that have been cut and repaired in the conventional manner and those that have employed the rotary coring and reinstatement process.

Golder Associates, which monitored the effectiveness of the Utilicor keyhole reinstatement process over a ten year period (read more), found that the pavement core, or coupon, reinstated with Utilibond bonded the remaining slab of pavement in such a manner that the loads of traffic were effectively transmitted to the remaining intact slab and the reinstated road again performed in accordance with its original design. Not only is the process more efficient and environmentally friendly (read more), but it can also add years of life to the road (as compared to other forms of utility cuts and repair) and will ultimately save taxpayers money.

How Pavements Carry Load

Surface load is concentrated downward in a vertical plane directly into the sub-grade as wheel loads roll across a paved surface. In an uncut roadway this load is evenly distributed. However, in the case of a typical utility excavation repair, there is a concentrated stress which is transferred onto the sub-base, which will result is premature degradation of the road base. In a keyhole core utility cut reinstated with Utilibond™, where the core and the balance of the pavement have been reintegrated into a load-bearing system, the vertical load is laterally transmitted across the surface once again, and the roadway acts as a “system” distributing the load evenly as the road was originally designed to.

Utility Cuts, Pavement Performance, and the Keyhole Solution

Improperly restored utility cuts can affect pavement performance and contribute to deterioration and reduced pavement life. Keyhole technology procedures and reinstatement processes are designed to minimize the impact of utility cuts on roadways and other paved surfaces by reinstating the paved surface to the operating condition that preceded the repair.

Uncut Road

(Distributed Load)

Conventional Pavement Cut

(Concentrated Stess)

Utilibond Reinstated Core

(Distributed Load)U

Size Does Matter

Surgeons have recognized that fact in the medical field for years now. Smaller is better. Laparoscopic surgery is less intrusive and causes less trauma and tissue damage to the patient, which leads to a shorter recovery period. The smaller incision also heals faster and leaves a smaller scar. It is also cheaper because it consumes fewer resources in the hospital and has less impact on the patient during recovery. These same factors apply to cored keyholes in roadways.

The hole is smaller and more precise, with no trauma from pounding jackhammers and backhoes, and the the neat, almost invisible circular keyhole excavation is also more aesthetically pleasing and is less than a quarter of the area of a conventional 2ft. x 4 ft. rectangular road cut.